Overheated electrical panels can cause big problems for you. They might harm equipment, start fires, or cost a lot to fix. For example:

- 1.4 million electrical panels were recalled because of overheating.

- Another 289,000 panels in Canada had the same problem.

You shouldn’t take chances with these dangers. A cabinet cooler helps by keeping panels cool and protecting your equipment.

Key Takeaways

- Hot electrical panels can cause fires and expensive repairs. Check the panel’s heat to avoid these problems.

- Cabinet coolers keep electrical panels at safe temperatures. They stop heat and moisture from damaging equipment.

- Clean filters and check connections often to stop overheating. This easy task can save repair costs.

- Pick the right cabinet cooler for your panel’s location. Think about dust, moisture, and heat when choosing a system.

- Talk to experts to pick the best cooling system. Their advice can save you time and money later.

The Risks of Overheating in Electrical Panels

Causes of Overheating

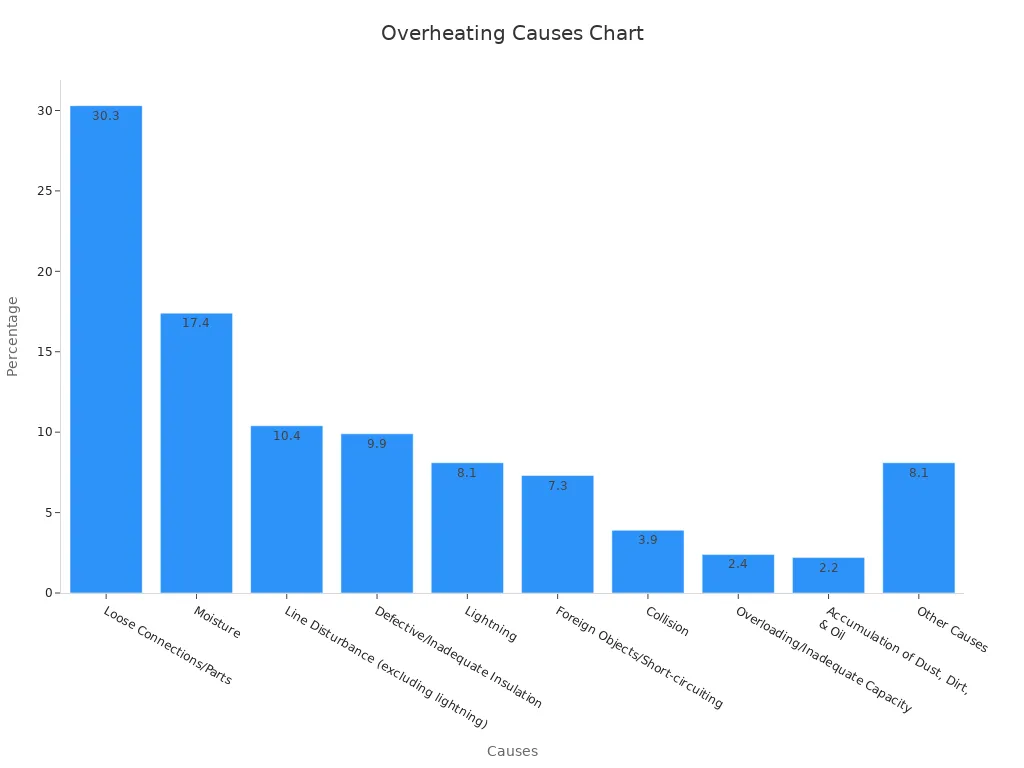

Electrical panels can overheat for many reasons. Knowing these causes helps avoid damage. A study shows the most common reasons:

| Cause of Overheating | Percentage |

|---|---|

| Loose Connections/Parts | 30.3% |

| Moisture | 17.4% |

| Line Disturbance (excluding lightning) | 10.4% |

| Defective/Inadequate Insulation | 9.9% |

| Lightning | 8.1% |

| Foreign Objects/Short-circuiting | 7.3% |

| Collision | 3.9% |

| Overloading/Inadequate Capacity | 2.4% |

| Accumulation of Dust, Dirt, & Oil | 2.2% |

| Other Causes | 8.1% |

Loose connections and moisture are the biggest problems. Together, they cause almost half of the overheating cases. These issues often go unnoticed until damage happens. Dust and dirt can also block airflow and cause overheating. Using a cabinet cooler keeps your panel clean and safe.

Consequences for Equipment and Safety

Overheating harms more than just the panel. It can damage your whole system. Wires carrying too much current get hot. If heat builds up, wires can burn or start fires.

- Hot wires and cords often cause electrical fires.

- Bad insulation or broken wires can lead to short circuits.

- Skipping inspections can hide overheating problems, risking safety and property.

Fixing these problems protects your equipment and keeps everyone safe. Cabinet coolers control temperature and stop dust and moisture from hurting your system.

Financial Implications of Overheating

Overheating can cost a lot of money. Repairs and replacements are expensive. Here’s what you might pay:

| Service | Cost Range |

|---|---|

| Moving the panel | $1,500–$4,000 |

| Fixing drywall | $1.50–$3 per sq ft |

| Digging trenches | $600–$2,100 |

| Adding outlets | $125–$200 each |

| Replacing bad wiring | $600–$4,500 |

These costs don’t include lost time or work delays. Preventing overheating with a cabinet cooler saves money over time. It’s a smart way to protect your system and avoid big expenses.

Why a Cabinet Cooler is Essential

Keeping the Right Temperature

Your electrical panel needs to stay cool to work well. If it overheats, equipment might break, work could stop, and repairs can get expensive. A cabinet cooler helps keep the panel cool, even in tough conditions.

Here’s how cabinet coolers improve cooling:

| Metric | What It Does |

|---|---|

| Power Usage Effectiveness (PUE) | Shows how much energy is used for cooling versus equipment. |

| Cooling Capacity Factor (CCF) | Helps manage airflow for better cooling. |

| Cooling Effectiveness | Finds hot and cold spots to ensure even cooling. |

| Raised Floor Bypass Open Area | Check the airflow delivery to improve cooling. |

| Perforated Tile Placement | Studies tile placement to manage airflow better. |

| Bypass Airflow | Measures air skipping equipment to ensure efficient cooling. |

Adding a cabinet cooler gives you control over these factors. It keeps your panel safe and working properly.

Stopping Dust and Moisture

Dust and moisture can quietly harm your electrical panel. They can cause rust, short circuits, and damage. Cabinet coolers block these problems by keeping the panel clean and dry.

Why Cabinet Coolers Help with Dust and Moisture:

- Seal the panel to keep dust and water out.

- Control humidity to protect delicate parts.

- Meet cleanliness rules for safe and clean panels.

In industries like food processing, cabinet coolers are extra helpful. They handle water sprays, cleaning chemicals, and tough conditions. Their smooth, rust-proof design keeps panels safe in harsh places.

Making Equipment Last Longer

Cabinet coolers don’t just protect—they make your panel last longer. By stopping overheating and dirt, they help your equipment run better for years.

| Benefits of Cabinet Coolers | What They Do |

|---|---|

| Stop Overheating | Prevent heat damage to keep equipment working. |

| Protect Equipment from Breaking | Save important parts from failing. |

| Lower Maintenance Costs | Cut down on repair and replacement expenses. |

| Extend Life of Key Parts | Help parts like VFDs and PLCs last longer, saving money. |

Using a cabinet cooler means fewer problems, less money spent on repairs, and more reliable equipment. It’s a smart way to protect your panel and improve its performance.

Types of Cabinet Coolers

Active Cooling Systems

Active cooling systems use advanced tools to keep panels cool. They mix liquid and air methods for better performance. Studies show this method improves cooling by 60% over regular air-cooling. It can remove over 19,000 kJ of heat and works with 89% efficiency.

These systems are great for hot places or heavy workloads. They keep panels cool and stop overheating, which might harm equipment.

Tip: Use active cooling in industries needing exact temperature control, like data centers.

Passive Cooling Systems

Passive cooling uses natural airflow to keep panels at safe temperatures. These systems save energy and cost less, making them ideal for easier jobs.

Why passive cooling is helpful:

- Uses 75% less energy than regular cooling units.

- Two circuits adjust to temperature changes for better cooling.

- Adapts to conditions, helping equipment last longer.

Passive cooling is perfect for saving money while protecting panels.

Vortex Coolers

Vortex coolers use compressed air to cool panels. They are strong, easy to maintain, and keep panels clean and dry.

| Feature | What It Does |

|---|---|

| Cooling Efficiency | Lowers air temperature by 50°F (28°C) or more. |

| Maintenance | Needs little care, mostly filter changes. |

| Durability | Built tough for long-lasting cooling. |

| Operational Benefits | Stops oil and dust from entering the panel. |

Vortex coolers work well in factories where downtime costs money. Their smart design makes them a dependable choice for panel protection.

Note: Vortex coolers are great for dusty or oily environments.

Open-Loop vs. Closed-Loop Systems

Picking between open-loop and closed-loop systems affects cooling success. Both have their own benefits. Knowing the differences helps you choose wisely.

Open-Loop Systems

Open-loop systems cool panels using air from outside. They pull in air, move it through the panel, and push it back out.

Advantages of Open-Loop Systems:

- Easy to set up and take care of.

- Costs less than closed-loop systems.

- Best for places with clean, steady air.

But, open-loop systems don’t work well in dirty or wet areas. Dust and water can get inside and harm the panel.

Tip: Use open-loop systems in clean indoor areas with good air quality.

Closed-Loop Systems

Closed-loop systems keep the panel sealed. They use inside air to cool, blocking outside air completely. This keeps dust, water, and heat changes away.

Advantages of Closed-Loop Systems:

- Great at keeping out dirt and moisture.

- Works well in tough or outdoor places.

- Helps equipment last longer by avoiding damage.

Closed-loop systems cost more at first but last longer. They are worth it for hard conditions.

Why Choose Closed-Loop Systems:

- For factories, warehouses, or outdoor use, closed-loop systems protect best.

Which System is Right for You?

The right system depends on your space and needs. Open-loop systems save money and work in clean areas. Closed-loop systems are better for rough conditions. Adding a cabinet cooler makes sure your panel stays safe and works well.

Choosing the Right Cabinet Cooler

Understanding Heat and Panel Design

Picking the right cooler starts with knowing your panel’s heat. All panels make heat, but the amount depends on the equipment inside. To find the total heat, check how much power your parts use and the heat they create.

The design of your panel matters too. Panels with bad airflow or tight spaces hold heat. This raises the chance of overheating. If your panel is crowded, you need a cooler that works better. By checking these things, you can choose a cooler that fits your panel and keeps it working well.

Thinking About Surroundings

Where your panel is placed affects how cooling works. Before choosing, look at the area around your panel:

- Hottest temperature: Know the highest heat your panel will face.

- Dust and dirt: See if the area has lots of dust.

- Rust risk: Check for chemicals or vapors that might cause rust.

- Water exposure: Find out if water might splash or spray the panel.

- Humidity: Look for moisture that could form inside the panel.

Ignoring these things can harm your panel. For example, dusty places need coolers that block dirt. Wet areas need coolers that stop water damage. Fixing these problems helps your panel last longer.

Saving Energy

Energy-saving coolers are important when picking a system. A good cooler lowers energy costs and works well. Look for coolers with smart features like fans that change speed or modes that save power. These features adjust cooling to match your panel’s needs.

Efficient coolers save money and help the environment. They use less power, which cuts down pollution. Choosing an energy-saving cooler is good for your wallet and the planet.

Seeking Expert Guidance

Picking the right cooling system for your electrical panel can be tricky. There are many choices, and it’s hard to know where to begin. Asking experts for help makes sure you choose the best option. They can save you time, effort, and money by avoiding mistakes.

Here are simple tips experts suggest for choosing a cabinet cooler:

- Plan Cooling Early! Think about cooling needs when designing your panel. This avoids costly fixes later.

- Ventilation or Closed-Loop? Use outside air if it’s clean. If not, pick a closed-loop system to block dirt and moisture.

- Fan or Blower? Check how much airflow your panel needs to pick the right cooling tool.

- Pressurize, Don’t Vacuumize! Push clean air into the panel to keep dust out.

- Clean Filters Often: Keep filters clean so your cooling system works well.

- Separate Air Paths: Place air intake and exhaust far apart for better cooling.

- Use Natural Airflow: Position vents to use natural air movement for cooling.

Following these tips keeps your electrical panel cool and safe. Experts can also guide you on tough choices, like picking between open-loop or closed-loop systems. Their advice helps you find the best solution for your setup.

Don’t risk damage to your electrical panel. Contact an expert today to get a cabinet cooler that protects your equipment and makes it last longer.

Overheating in electrical panels can cause big problems. It may lead to system breakdowns or even safety dangers like fires. A cabinet cooler helps by keeping the panel cool and clean. It stops heat and dirt from harming your equipment.

| Problems from Overheating | How Cabinet Coolers Help |

|---|---|

| Systems stop working due to high heat | Better equipment performance |

| Expensive repairs and upkeep | Less downtime |

| Fire risks from overheated wires | Longer-lasting equipment |

| Work delays and lost time | Saves energy |

Protect your equipment today. Save money and keep your system running smoothly with this smart solution.

FAQ

What is a cabinet cooler, and why do you need one?

A cabinet cooler keeps your electrical panel from getting too hot. It stops overheating, protects equipment, and saves money on repairs. It helps your system work well and stay safe in tough places.

How do cabinet coolers handle dust and moisture?

Cabinet coolers block dust and water from getting inside. They keep humidity low and stop rust or short circuits. Their design keeps your equipment clean and safe, even in hard conditions like factories or outdoors.

Are cabinet coolers energy-efficient?

Yes, many cabinet coolers save energy with smart designs. They use fans that change speed and cooling modes that adjust. These features use less power, cut costs, and help the planet.

Which industries benefit most from cabinet coolers?

Factories, food plants, and data centers use cabinet coolers the most. They handle heat, dust, and water well. Cabinet coolers protect equipment and keep it working in busy places.

How do you choose the right cabinet cooler?

First, check how much heat your panel makes and its surroundings. Look for dust, water, and temperature issues. Ask an expert to help you pick the best cooler. The right choice keeps your panel safe and saves money over time.