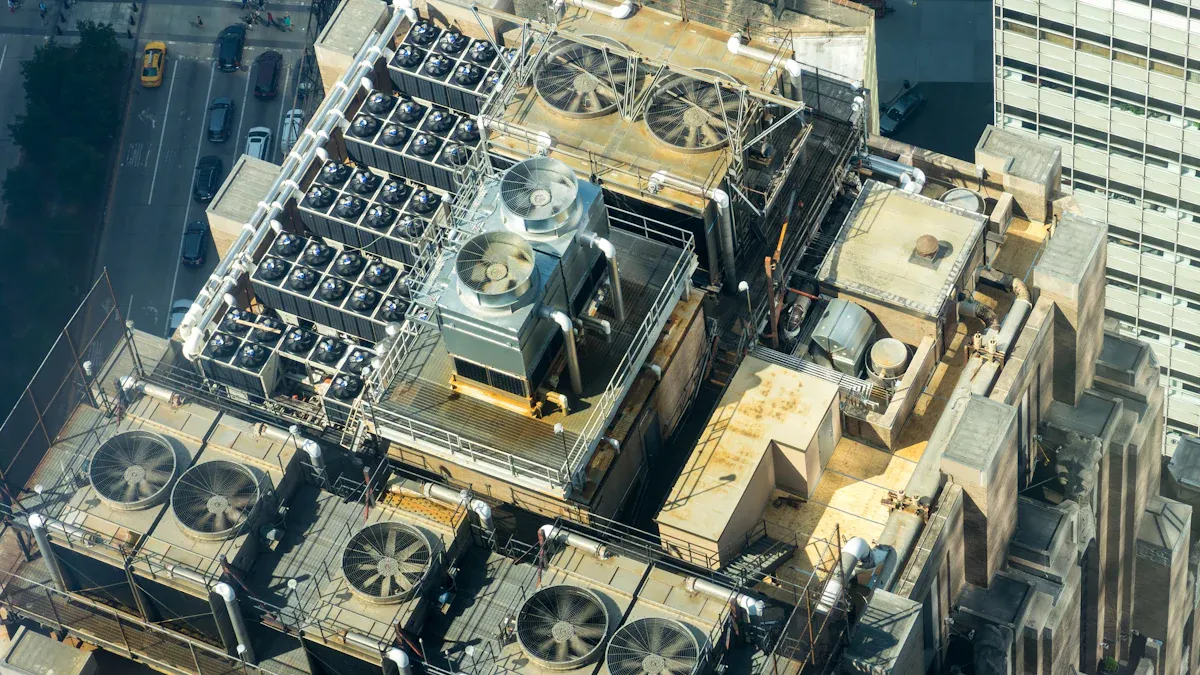

Industrial air conditioner systems are very important in modern industry. They help keep processes the same, protect workers, and make work faster. The market is now worth USD 136.7 billion. More people want new solutions like the cabinet air conditioner.

Companies use these systems to keep equipment safe, control heat, and keep the air clean.

| Metric | Value |

|---|---|

| Current Market Valuation | USD 136.7 billion |

| Number of Companies | 23,500+ |

| Patents | 521,200+ |

| Leading Technologies | VRF, UV sterilization, solar-powered AC |

Key Takeaways

- Industrial air conditioners help save energy. They make factories work better by using efficient systems. They also use methods that are good for the environment.

- Smart technology like IoT and AI helps watch and control air conditioners. This lowers the time machines are not working. It also helps cut down on energy bills.

- Good air quality and humidity control keep workers healthy. They also help machines work well without problems.

- Industrial air conditioners keep production steady. They keep workers safe by keeping the temperature and humidity right.

- Advanced cooling solutions, like liquid cooling and AI controls, help data centers and factories. These solutions help them handle more work and save energy.

Energy Efficiency

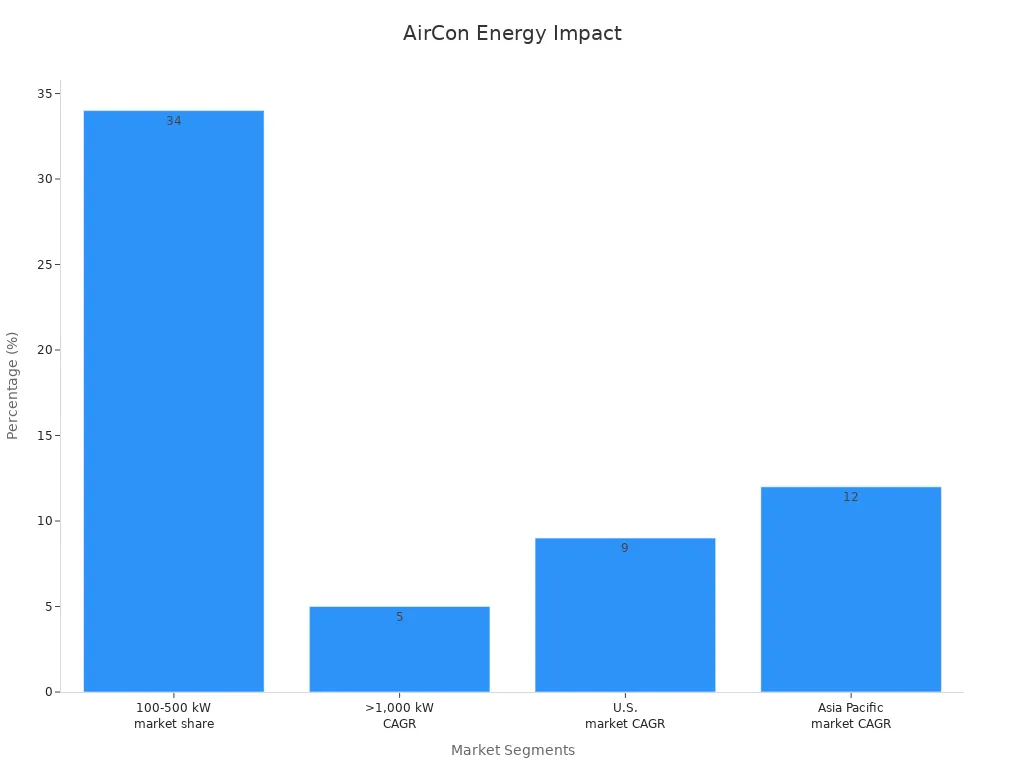

Industrial air conditioners help big factories use less energy. Companies want cooling that works well but does not waste power. Many businesses now pick energy-efficient systems. The 100-500 kW group is very popular. It makes up more than 34% of the market in 2024. This means many factories use these efficient coolers. Bigger systems, over 1,000 kW, are also getting more popular. Their demand is growing by more than 5% each year from 2025 to 2030. The U.S. and Asia Pacific are growing fast too. The U.S. grows by over 9% each year. Asia Pacific grows by over 12% each year. This happens because of new energy rules and better technology.

High-Efficiency Systems

High-efficiency systems use new technology to cool better and waste less. Companies look at important numbers to pick the best system. The table below shows what these numbers mean and why they matter:

| Metric | Definition | Practical Insight |

|---|---|---|

| EER (Energy Efficiency Ratio) | Cooling capacity (Btu/h) divided by electrical input (W) | Higher EER means better efficiency |

| SEER (Seasonal Energy Efficiency Ratio) | Efficiency over the entire cooling season | Upgrading from SEER 10 to SEER 25 can save about 60% energy |

| COP (Coefficient of Performance) | Ratio of heat removed to energy input | Higher COP means more efficient operation |

| kW per ton of cooling | Energy used per ton of cooling | Lower values show better chiller efficiency |

Modern systems like Cooltechx use inverter technology and energy recovery ventilators. These features help keep high SEER and EER numbers. This makes them great for tough jobs in factories.

Sustainable Methods

Sustainable methods help save even more energy. Companies use air handling units with heat recovery. They also use energy management systems and better exhaust fans. These changes make systems work much better. For example, air handling units with heat recovery can boost efficiency by 43.75%. Energy management systems can save about 14.07% energy. Fixing duct leaks can make energy use better by 30%. Using water from the AC for spraying can raise the coefficient of performance by 16%.

| Sustainable Method | Energy Savings / Efficiency Improvement |

|---|---|

| Air handling unit with heat recovery | 43.75% efficiency increase |

| Energy Management Systems (EMS) | ~14.07% average energy savings |

| Duct leakage repair | 30% improvement in energy usage |

| Exhaust fan improvements | 25% increase in efficiency |

| Condensate water spraying in portable AC | 16% increase in COP |

Tip: Using both high-efficiency systems and sustainable methods helps companies save money and protect the environment.

Smart Integration

Smart integration has changed how companies use these systems. Now, smart technology helps them work better and save money. Facility managers can see data right away. They can make quick choices. This helps them find problems early. They can fix things before they get worse.

IoT Connectivity

IoT connectivity lets air conditioners connect with other machines. Sensors collect data about temperature and humidity. They also track energy use. The system sends this data to a main dashboard. Managers can check the dashboard from anywhere. They can see if something is wrong. They can act fast to fix it.

| Impact Area | Measurable Impact | Explanation | Real-World Example |

|---|---|---|---|

| Unplanned Downtime Reduction | 35-45% decrease | IoT sensors help find problems early. This stops surprise breakdowns and saves time. | Dubai International Airport’s HVAC predictive maintenance cut downtime and costs. |

| Equipment Life Extension | Up to 40% longer lifespan | Watching equipment all the time helps it last longer. | Same as above |

| Energy Savings | 20-30% energy reduction | Smart thermostats and sensors help save energy. | Smart building controls with IoT sensors save up to 30% energy. |

| Maintenance Efficiency | Improved through remote diagnostics and scheduling | Real-time data and alerts help managers fix things faster. | IoT remote monitoring means fewer trips and better repairs. |

IoT-enabled air conditioner systems help companies use less energy. They can cut energy use by up to 30%. They also lower unplanned downtime by up to 45%. Managers can use remote monitoring to plan repairs. This helps avoid expensive breakdowns.

Automation and AI

Automation and AI make these systems even smarter. AI uses sensor data to change cooling as needed. This means the system only uses energy when needed. AI can also spot problems early. It warns managers before things break.

- AI-powered maintenance can cut downtime by up to 45%.

- Energy savings can reach up to 40% with AI analytics.

- Automated fault detection is up to 95% accurate.

- Maintenance costs can drop by up to 40% with early fixes.

- Equipment can last up to 20% longer with AI maintenance.

Smart systems use real-time data to balance energy in different areas. Variable frequency drives change power to match what is needed. This lowers wear and saves money. These features help companies meet green goals and follow new rules. A study in Singapore showed a 7.8% drop in energy use after upgrades. This proves real savings.

Tip: Companies using automation and IoT in their air conditioner systems have fewer breakdowns, lower costs, and better results.

Air Quality Control

Factories need clean air to keep workers and machines safe. Air quality control is very important for every modern factory. New industrial air conditioner systems use smart sensors and filters. These help keep the air safe and comfortable.

Filtration Technologies

Modern filters take out bad particles and gases from the air. Health experts say to use filters rated at least MERV 13. These filters catch 85% of particles that are 1 to 3 microns big. HEPA filters can remove 99.97% of tiny particles as small as 0.3 microns. These filters help stop allergies and breathing problems.

- Main benefits of advanced filtration:

- Catches dust, pollen, and mold spores

- Cuts down on smells and bad gases

- Keeps HVAC equipment safe and lowers repair costs

- Makes indoor air better for workers

| Filter Type | Efficiency | Particle Size Removed | Maintenance Needs |

|---|---|---|---|

| MERV 13 | 85% | 1-3 microns | Moderate |

| HEPA | 99.97% | ≥0.3 microns | High |

Digital sensors watch for dust, carbon dioxide, and airflow. These sensors let managers see air quality right away. They can act fast if the air gets bad. Factories with good filters and sensors have fewer health problems. Their systems also work better.

Tip: Check and change filters often to keep air clean and systems working well.

Humidity Management

Good humidity control keeps indoor spaces safe and comfy. Industrial air conditioner systems use hygrometers, humidifiers, and dehumidifiers. These tools help control how much water is in the air. Keeping humidity between 40% and 70% RH protects machines and stops mold.

- Benefits of balanced humidity:

- Stops damage and mold

- Lowers health risks for workers

- Helps cooling and airflow work better

Smart humidity sensors and software give real-time data. Managers can find problems early and fix them fast. Putting sensors near important machines helps keep things steady. Facility management software gives alerts and shows trends. This makes it easier to keep humidity safe.

A well-managed space helps workers stay healthy and machines last longer. Industrial air conditioner systems with good humidity control save energy and lower repair needs.

Industrial Air Conditioner Applications

Process Consistency

Industrial air conditioners help keep production steady. Many factories need the right temperature and humidity. This helps them make good products. In plastics and rubber factories, small climate changes can cause problems. Machines may slow down or make bad products. Food and beverage plants also need stable air. This keeps food safe and fresh.

Some real stories show how these systems help. A factory in Lexington, KY, got new compressors and controls. This upgrade made machines stop less often. Production went up. Workers felt better at work. The company had fewer problems in their process. A digital printing expert shared his story too. He said good climate control keeps print quality high. It also helps machines work well. Modern systems use smart technology. They watch and change settings as needed. This helps factories avoid trouble and stay steady.

| Industry | Application Focus | Benefit Achieved |

|---|---|---|

| Plastics/Rubber | Temperature control | Fewer defects, steady flow |

| Food & Beverage | Humidity management | Product safety, freshness |

| Digital Printing | Air quality, precision | Consistent output, less waste |

Note: Keeping the climate steady helps make better products and stops delays.

Worker Safety

Industrial air conditioners keep workers safe. Big factories can get very hot. This heat can make workers sick or tired. Good air conditioning lowers these risks. It makes the workplace safer. Studies in Europe found that air conditioning helps a lot. Workers in cool factories have fewer health problems. They also lose less work time than those in hot places.

- Air conditioning in factories lowers heat stress.

- Workers are safer and feel better.

- Cool air helps workers lose less work time.

Big factories, like plastics, rubber, and food plants, see the most benefits. Clean, cool air helps workers focus. It also lowers the chance of accidents. Managers see fewer sick days and happier workers when the air is safe.

Data Center Cooling

Data centers must keep servers cool and safe. If the temperature or humidity changes, it can cause trouble. Industrial Air Conditioner systems help keep things steady. Companies use these systems to protect data and keep everything working.

Precision Climate Control

Modern data centers use smart controls for temperature and humidity. The air stays between 24 °C and 25.5 °C. Humidity is controlled to stop static and water drops. Hot aisle and cold aisle setups help move air the right way. Sensors check the air every second. This helps managers find problems fast and keep things running.

| Aspect | Details |

|---|---|

| Temperature Control | 24–25.5 °C supply air; 10–14 °C delta-T for efficiency |

| Humidity Control | Prevents static and corrosion; keeps equipment reliable |

| Energy Use | Cooling can use up to 33% of total data center energy |

| Efficiency Metric | PUE: legacy ~2.0, hyperscale <1.2, global average ~1.67 |

| Reliability | Redundancy and predictive maintenance ensure uptime |

AI-powered cooling systems look at sensor data all the time. They change settings to save energy and keep things safe. By 2025, most big companies will use AI for data centers. AI cooling can cut energy use by up to 40%. It can also lower costs by 15-20%.

Advanced Cooling Solutions

As data centers get bigger, air cooling is not enough. Liquid cooling is now a popular choice. Liquids remove heat much better than air. This helps companies run strong servers for AI, games, and finance. Liquid cooling platforms keep things cool and fast.

- Liquid cooling lets companies use more powerful equipment.

- At 10 kW per rack, liquid cooling costs about the same as air cooling. At higher power, it can save 10-14% in costs.

- Some systems combine cooling, power, and networking for easy setup.

Cooltechx is a leader in advanced cooling products. Their systems use special compressors, EC fans, and smart controls. These features help save energy and lower downtime. They also help data centers meet green goals.

Note: Using liquid cooling and AI controls helps data centers handle cloud computing, big data, and IoT.

Climate Adaptation

Extreme Environments

Industrial air conditioners have harder jobs now. Extreme weather happens more often than before. In 2024, heatwaves went up by 15%. Factories and data centers need better cooling systems. Places like India and Europe have longer, hotter summers. These places need strong air conditioning that works well.

| Challenge | Description | Solutions |

|---|---|---|

| Fouling and Contamination | Dirt and biofilm can cover heat exchangers. This makes them work less well and can hurt health. | Water treatment, anti-fouling coatings, closed-loop systems, and regular cleaning help stop this. |

| Scaling and Mineral Deposits | Minerals can build up on cooling parts. This causes rust and makes heat move badly. | Water softening, anti-scalants, dry coolers, and regular checks help fix this problem. |

| High Energy Consumption | Cooling uses more power during heat waves. This costs more money and can stress the power grid. | Economizer modes, adiabatic pre-cooling, EC fans, energy recovery, and variable speed drives help save energy. |

| Complex Maintenance | More repairs mean more stops in work, which is hard for some factories. | Smart controls, hybrid systems, sealed dry loops, and predictive maintenance make repairs easier and faster. |

Many companies use new ideas like hybrid cooling and smart controls. Closed-loop systems are also popular now. These changes help keep things running even when it is very hot. In India, new rules say truck cabins must have air conditioning by October 2025. This keeps drivers safe from dangerous heat.

Resilience Strategies

Big factories and buildings need to be ready for climate risks. They buy systems that can change with the weather. They also plan for problems with getting supplies. The HVAC market is growing by 6.8% each year. This is because of new air quality rules and laws. The EPA now says companies must use low-GWP refrigerants. Old types like R-410A are being stopped.

Key ways to adapt to climate change include:

- Using energy-efficient models, now in over 75% of new projects.

- Using AI-driven predictive maintenance to stop breakdowns and help equipment last longer.

- Upgrading to smart HVAC systems that change settings by themselves.

- Training more technicians to help with the 80,000-worker shortage.

- Buying products that protect people from heat and help air stay clean during wildfires.

Note: As the world gets hotter, companies will spend more on climate adaptation than on stopping climate change. Companies that act soon will keep their workers, machines, and profits safe.

Sector Innovations

Food and Beverage

The food and beverage industry needs good cooling to keep food safe. Companies use smart air conditioning to watch temperature and humidity all the time. These systems stop food from going bad and keep it fresh. The market for these coolers is growing fast in Asia-Pacific and North America. This is because it is getting hotter, there are new rules, and people want to save energy.

- Companies use hybrid cooling and heat recovery to save power.

- IoT and AI help managers check systems and fix problems early.

- Water-cooled systems work well when there is a lot of heat, so food plants like them.

Companies like Johnson Controls Inc. and SPX Corporation make systems that follow safety and green rules. The global market for these coolers was $22.58 billion in 2024. It keeps growing as companies want coolers that are easy to use and do not break often.

Pharmaceuticals

Pharmaceutical plants must control temperature and humidity very carefully. The newest HVAC systems use sensors and alarms to keep things steady. These systems stop germs from growing and protect important products. The ISPE report says good filters and set points are very important in these plants. Companies use better air cleaning and humidity control to meet new rules. These changes help keep products safe and lower the chance of germs.

Note: Good air conditioning is very important for keeping medicine safe and working well.

Manufacturing

Manufacturing plants get better with new air conditioning that saves energy and helps the planet. New systems use light, strong parts and can be put together easily. AI and IoT help fix problems before things break down. One company saved $30,000 a year and cut 423 tons of CO2 by using a new Industrial Air Conditioner. This shows that new HVAC systems help save money and protect the environment.

- Using solar and geothermal energy cuts pollution.

- Modular units can be used in many parts of a factory.

- Training workers helps them use and take care of green systems.

Industrial Air Conditioner systems help factories in many ways. They keep work steady and workers safe. These systems also help save energy. Companies get better products and safer places to work. Many businesses want to upgrade or add new systems. They do this to follow new rules. Some look at advanced options like Cooltechx for more savings. These smart choices make factories stronger in 2025.

FAQ

What industries benefit most from industrial air conditioners in 2025?

Food and beverage, pharmaceuticals, manufacturing, and data centers get the most help. These places need the right temperature and humidity to stay safe. Good control keeps products high quality and machines working well.

How do smart air conditioners reduce energy costs?

Smart systems use sensors and AI to change cooling as needed. This helps cut energy use by up to 30%.

Tip: Automatic controls stop waste and help companies save money.

Why is air quality control important in factories?

Clean air keeps workers and machines safe. Special filters take out dust, pollen, and bad gases.

| Benefit | Result |

|---|---|

| Healthier staff | Fewer sick days |

| Safer machines | Less downtime |

What is the role of humidity management in industrial settings?

Humidity control stops mold and keeps products safe. It also helps machines work better. Sensors and software watch levels and warn managers if things change.

- Balanced humidity keeps people safe

- Good control helps machines last longer

Are advanced cooling solutions like liquid cooling worth the investment?

Yes. Liquid cooling works well for big data centers and factories with lots of heat. It makes cooling better and lets strong equipment run safely.

Note: Companies using liquid cooling often pay less for energy and have fewer problems with their systems.